Screw Press

- Forgings from 5 to 750 pounds up to 30" diameter

- Forging Flexibility: Controlled Press Parameters

- Cycle Time Reduction: Multi-Step Forging in One Heat

- Dies Preheated and Maintained at 400F

- 20 Minute Die Changes

- Die Sizes: 16”, 24”, 30”, 36” Diameter

- Two 17’ Diameter Rotary Furnaces

- Computer Controlled Interface

- Capability to +/- 15°F

- Manipulator for Consistent Transfer Times

- Full Press & Furnace Data Acquisition

- World Class Forging Productivity

Drop Forge

- Hammers from 5,000 lbs to 50,000 lbs

- Forgings from 5 to 750 pounds up to 48" diameter

- Support Presses up to 1,500 tons

- Complete In House Die Preparation and Maintenance

Die Shop

- Eight CNC Lathes

- One Vertical Turning Center

- Two Milling Centers

- Two Horizontal Lathes

- Water Jet

Heat Treat

- Automated Continuous and Batch Furnaces

- Air, Oil or Water Quench (< 10 sec)

- Control Capability to +/- 15°F

- Full Instrumentation, Monitoring and Recording with Backup

- Periodic Surveys

- NADCAP & AS9100 Approved

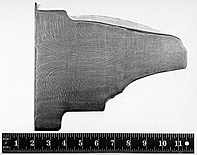

Laboratory

- Detailed Raw Material Acceptance and Overinspection

- Forging Cut Up and Evaluation

- Full Macrographic, Micrographic and Photographic Capability

- Process Research & Development

- NADCAP & AS9100 Approved

Non-Destructive Testing

- Penetrant Inspection Line

- Hardness Testing

- Micrographic Evaluation of Forgings

- Dimensional Inspection

- Coordinate Measuring Machine (CMM)

- Sertre Software

- Computerized Part Marking and Serialization

- NADCAP & AS9100 Approved

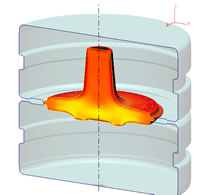

Engineering

- Full CAD/CAM Capability: Unigraphics, Solid Works, CATIA

- Advanced 3D Forge Modeling: Q-FORM

- Computer Integrated Die Design

- Numerically Controlled Die Sinking

- Electronic Data Interchange (EDI)